Lubrication

Water Trucks

Fluid Trans

Fuel & Evac

Why Choose Hyden as your Lubrication System provider?

Hyden is a distributor of all Major lubrication system manufactures.

Hyden is accepted by all Major OEM’s as a quality installer of lubrication systems

Hyden has a proven track record of providing outstanding after sale service and field service support

Hyden Engineering Lubrication Story

Formed in 1991, Hyden was quickly appointed a distributor of JSG and commenced the repairs and installations of Lincoln lubrication products. After establishing itself as a key supplier to OEM’s and mining customers, Hyden began expanding its product and support offering to include other brands such as Graco, Alemite, Tecalemit, etc.

In 2003, Hyden recognized the need for a new lubrication system and Easilube was developed and has since become our premium product offering with over 15,000 units in service fitted to equipment ranging from underground coal mining, machines, grape harvesters, skid steer loaders all the way up to large mining excavators.

Since then, Hyden has continued to develop custom-designed lubrication products as listed below:

Hyden Engineering Lubrication Story

Formed in 1991, Hyden was quickly appointed a distributor of JSG and commenced the repairs and installations of Lincoln lubrication products. After establishing itself as a key supplier to OEM’s and mining customers, Hyden began expanding its product and support offering to include other brands such as Graco, Alemite, Tecalemit, etc.

In 2003, Hyden recognized the need for a new lubrication system and Easilube was developed and has since become our premium product offering with over 15,000 units in service fitted to equipment ranging from underground coal mining, machines, grape harvesters, skid steer loaders all the way up to large mining excavators.

Since then, Hyden has continued to develop custom-designed lubrication products as listed below:

High flow grease overfill protection (No pressure vesicle certification required)

Custom bulk fill tanks

Automatic vent valves

Grease system controllers

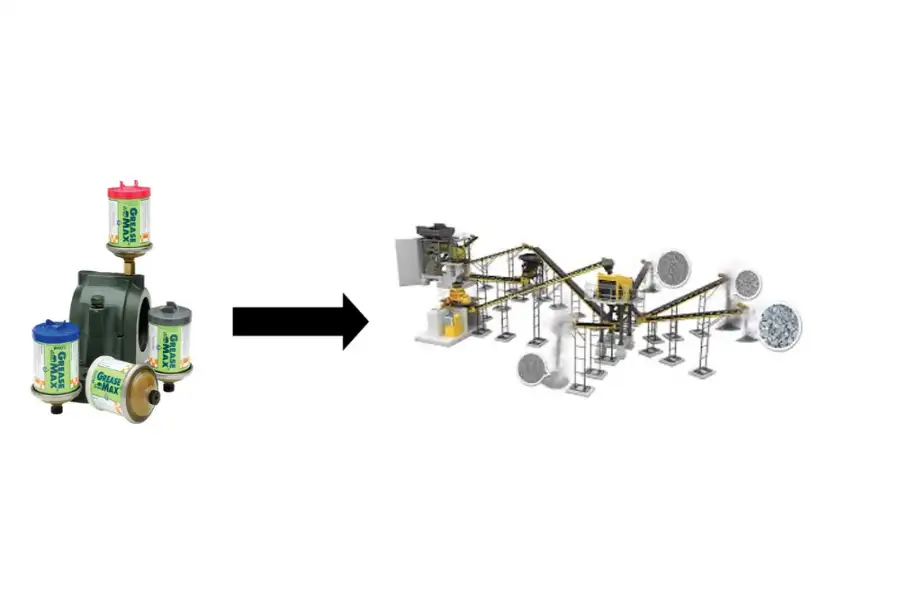

GreaseMax single point lubricators are ideal for conveyors, pumps, blowers, fans, electric motors and any lubrication point where a low volume constant supply flow is the solution you are looking for.

- 1, 3, 6, 12 month 125-cc versions available to suit your needs

- Tribol CL2, Moly and Food Grade greases available as standard

- Feedlines up to 2-m can be used for ease of installation

- Steel main body allows for hot applications and outlasts full plastic units

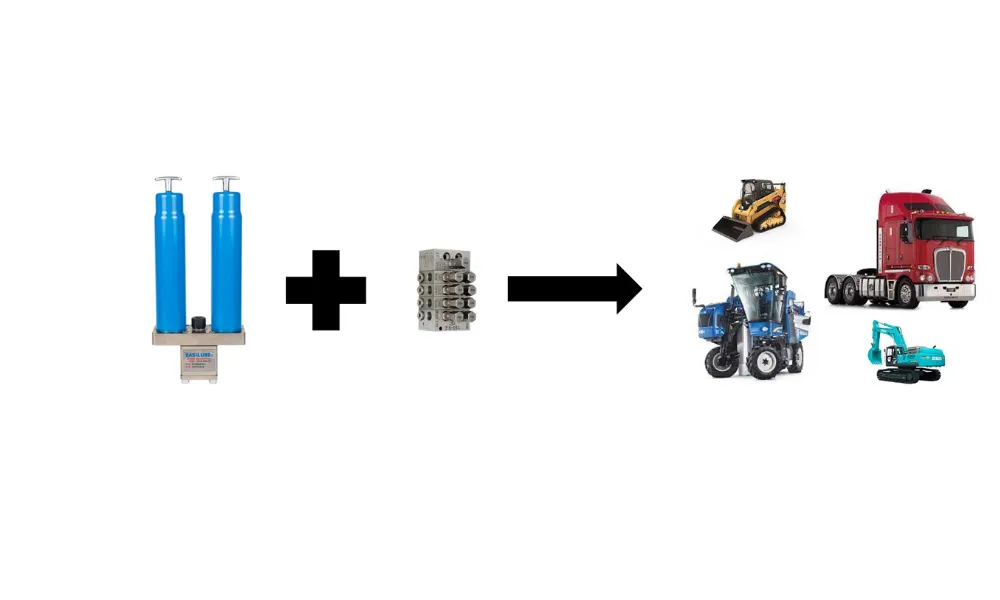

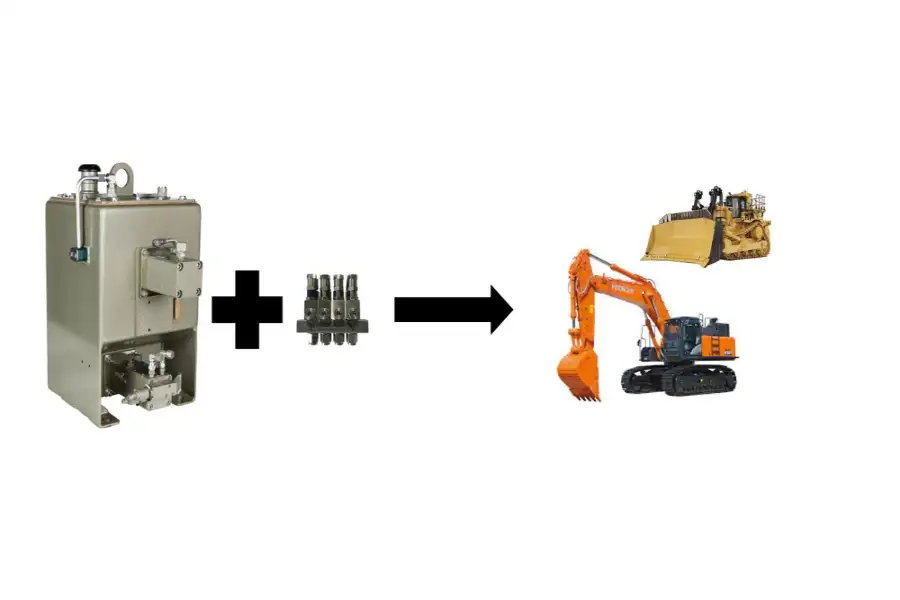

Hydraulic & Pneumatic Pump Versions paired with progressive valves are ideal for on-road, farming & small earthmoving equipment

- 400-gram and 450-gram versions available in single or twin cartridge setups

- Low level alarm kits available in both electric and pneumatic setups

- Grease cycle monitoring available for peace of mind

- Compact and amazing value

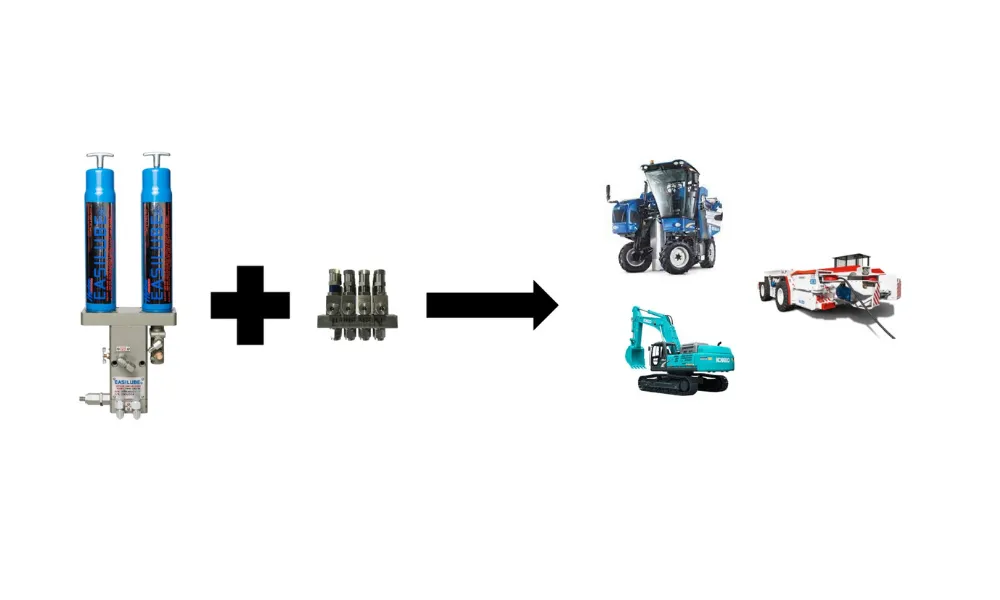

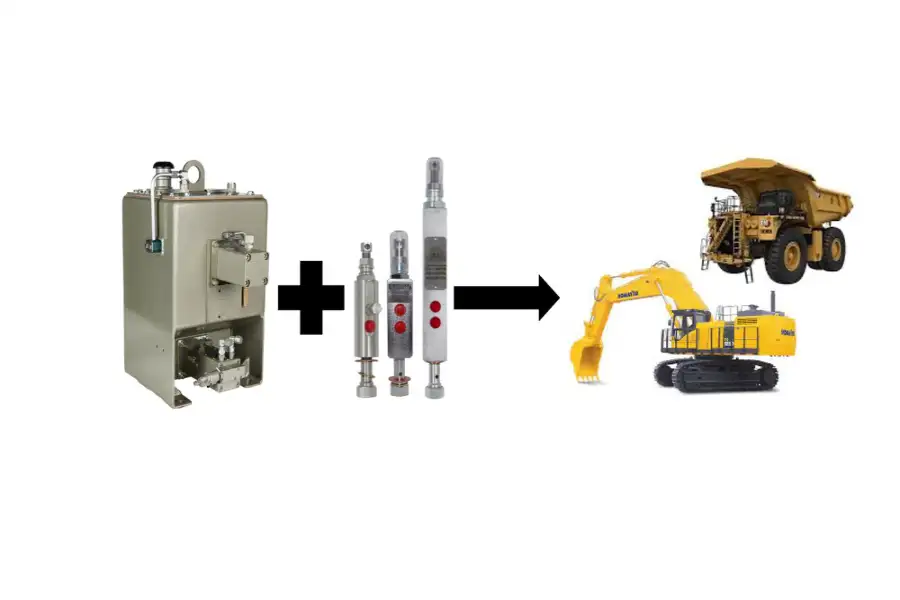

Hydraulic Pumps paired with compact injectors are ideal for underground mining, farming & small to mid size earthmoving equipment

- 400-gram and 450-gram versions available in single or twin cartridge setups

- Low level alarm kits available in both electric and pneumatic setups

- Grease pressure monitoring available for peace of mind

- Compact, flexible and incredibly robust

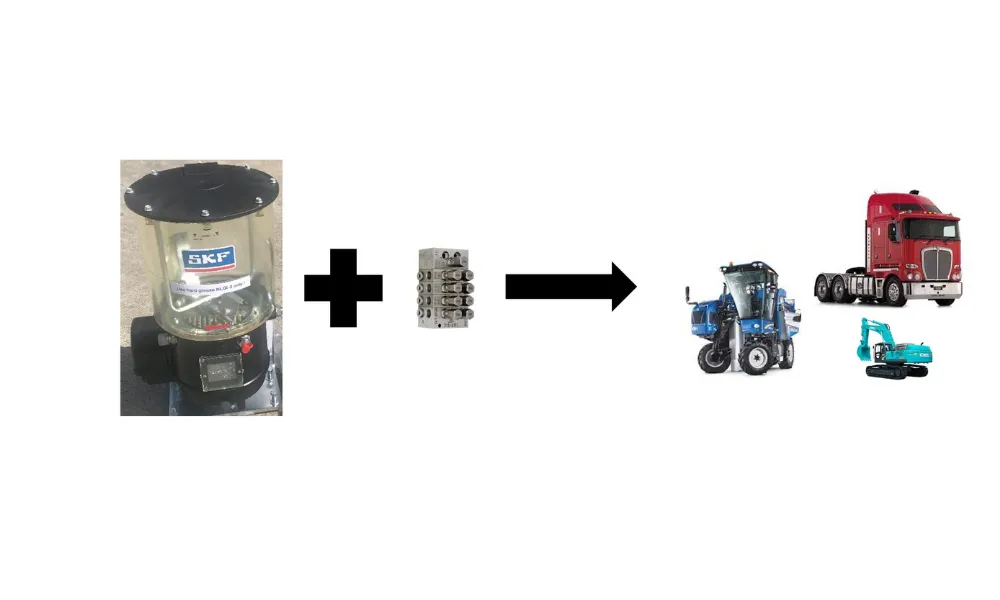

Electric pumps paired with progressive valves are ideal for on-road, farming & small to mid size earthmoving equipment where bulk fill is an option

- 6-Kg and 10-Kg versions available as standard

- Low level alarm as standard

- Grease cycle monitoring as standard for peace of mind

- Aluminium main housing outlasts full plastic pumps

Hydraulic Pumps paired with compact injectors are ideal for mid to large mining and earthmoving equipment

- 20-Kg, 30-Kg, 60-Kg and 90-Kg versions available as standard options

- High flow automatic shut off system and grease filtration options available without the need for pressure vesicle certification

- Grease pressure monitoring available for peace of mind

- High grease capacity, flexible and incredibly robust

Hydraulic Pumps paired with large injectors are ideal for large mining equipment

- 20-Kg, 30-Kg, 60-Kg and 90-Kg versions available as standard options

- High flow automatic shut off system and grease filtration options available without the need for pressure vesicle certification

- Grease pressure monitoring available for peace of mind

- High grease capacity, flexible and incredibly robust

Improve Equipment Efficiency with a robust Automatic Lubrication Systems

Unleash the full potential of your machinery by getting more productivity from your operators and maintenance staff by adopting a robust automatic lubrication system. Our solutions guarantee precise delivery of the right lubricant, in optimal quantities, at perfect intervals, targeting crucial lubrication points for unrivaled performance. Stop paying your highly skilled operators or maintenance technicians to do the work that an automatic lubrication system can do while the equipment is making you money and start realising the ROI our solution can provide.

Boost Machine Reliability, Slash Downtime

Whether you’re paying your highly skilled staff to manually pump grease into your equipment or using a generic, poorly designed, unreliable lubrication system, you are currently not seeing the true benefits a purpose designed solution can provide. Step into a world of heightened machine reliability and decreased dependence on scarce expertise. Our automatic lubrication systems are meticulously designed to provide the exact lubrication needed, exactly when it’s needed, reducing friction and wear and are designed using the most robust and reliable products on the market. This precision optimizes the lifespan of bearings and machinery, resulting in enhanced overall efficiency.

Benefits of Automatic Lubrication Systems

Experience a wealth of advantages by embracing automatic lubrication systems:

Save Big: Witness substantial reductions in repair and keep you’re skill staff on productive work.

Enhanced Reliability: Boost machine reliability, minimizing unexpected breakdowns.

Optimized Lubricant Usage: Achieve up to 50% savings in lubricant costs through precise timing and dosing.

Slash Downtime: Say goodbye to frequent shutdowns and production losses.

Eco-Friendly: Contribute to a reduced environmental impact through efficient lubrication.

Safety First: Prioritize workers’ safety by reducing manual tasks and greasy work.

Preserve Your Equipment, Extend Its Lifespan

Rethink equipment maintenance with our auto grease lubrication systems. Minimise wear and tear on valuable assets, extending their operational life while simultaneously lowering maintenance costs. Hyden Engineering’s automatic lubrication systems have proven their worth across a multitude of vehicles and equipment, making them a trusted choice in the industry.

Tailored Solutions for Every Need

Explore our extensive catalog of pre-designed auto grease systems, complete with accessories, specially crafted for heavy-duty mobile equipment. And if you need a custom solution, our auto lubrication systems are easily adaptable to fit specialty vehicles and unique applications.

Versatile Applications Across Industries

Our automatic lubrication systems find application in a diverse range of industries, including:

- Mining

- Earthmoving

- Quarries

- Construction, agriculture, and forestry machines

- On/Off-road machines

- Machine tools

- Automation

- Food and beverage

- Railroad applications

- Steel industry

- Pulp and paper

- Wind energy

- And more

Elevate your machinery’s performance, reduce costs, and ensure longevity with our Innovative-Elegant & Robust Solution to automated lubrication. Join the ranks of those already seeing the benefits of working with Hyden Engineering for all their lubrication needs.